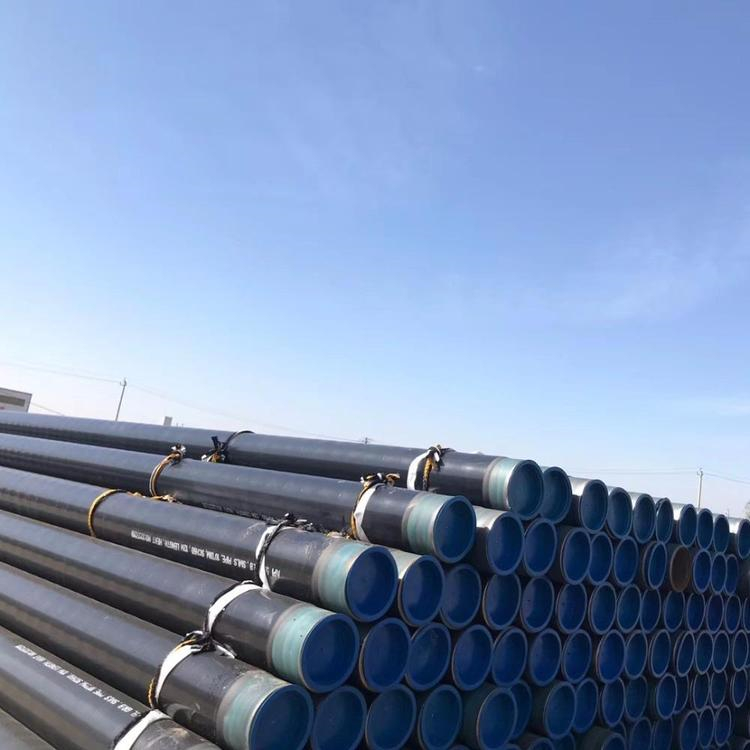

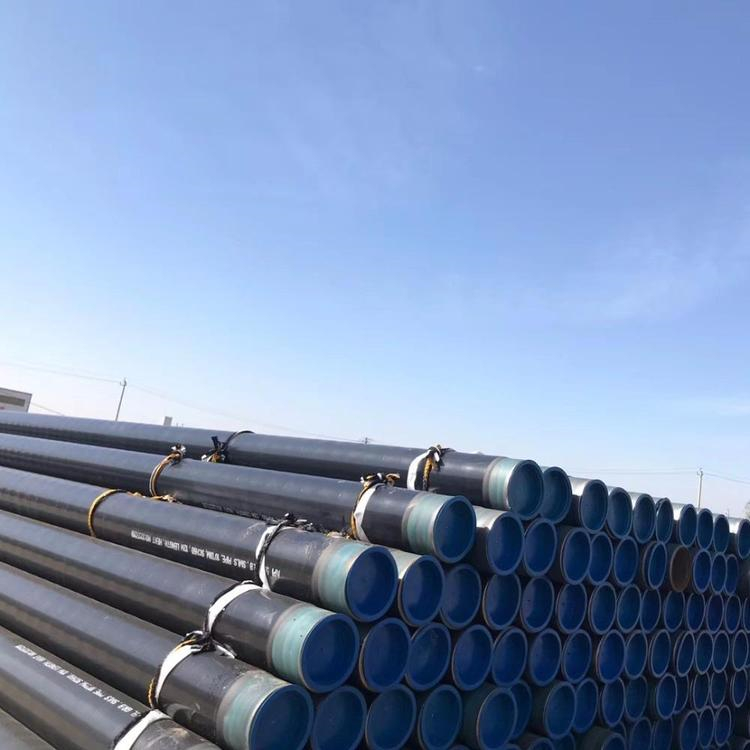

3PE anti-corrosion steel pipe

2PE-3PE anti-corrosion steel pipe

Material Analysis of 2PE-3PE Anti-Corrosion Steel Pipes

The base materials for 2PE-3PE anti-corrosion steel pipes include seamless steel pipes, spiral steel pipes, and straight seam steel pipes. The three-layer polyethylene (3PE) anti-corrosion coating, known for its excellent corrosion resistance, water vapor permeability, and mechanical properties, has been widely used in the petroleum pipeline industry.

Introduction to the Anti-Corrosion Layer of 2PE-3PE Coated Pipes

For buried pipelines, the anti-corrosion layer of 2PE-3PE coated pipes is crucial to their lifespan. Pipes made of the same material may remain uncorroded underground for decades while others experience leaks within just a few years. This is precisely because they employ different external anti-corrosion layers.

The 2PE-3PE anti-corrosion coating typically consists of a three-layer structure:

A layer of epoxy powder (FBE > 100μm)

Second-layer adhesive (AD) 170~250um

Three-layer polyethylene (PE) 2.5~3.7mm

In practice, the three materials are mixed and integrated, then processed to form a strong bond with the steel pipe, creating an excellent anti-corrosion layer. The processing methods generally include two types: winding and circular mold coating.

Advantages of 2PE-3PE anti-corrosion steel pipes:

The coating of 2PE-3PE anti-corrosion steel pipes consists of an epoxy powder anti-corrosion coating in contact with the steel pipe surface as the base layer, a copolymer adhesive with branched functional groups as the intermediate layer, and a high-density polyethylene anti-corrosion coating as the top layer. The 3PE anti-corrosion coating (three-layer polyethylene anti-corrosion coating) is a novel anti-corrosion steel pipe coating that ingeniously combines the European 2PE anti-corrosion layer with the widely used epoxy powder anti-corrosion coating (FBE) in North America.