The energy transmission 'artery' is upgraded again, and the new type of uncompensated steel sleeve steel insulated steel pipe solves the technical problem of high-temperature pipeline network

In the wave of industrial energy-saving transformation driven by the "dual carbon" goal, urban centralized heating and industrial high-temperature steam transmission pipelines are ushering in a new round of technological innovation. Recently, a new type of steel sleeve steel composite insulated steel pipe based on uncompensated cold installation technology has been successfully applied in multiple large-scale cogeneration and industrial park steam pipe network projects and completed its first year of operation evaluation. Its excellent energy-saving performance and safety stability have been highly recognized by the industry, marking a new stage in China's high-temperature prefabricated buried pipeline technology.

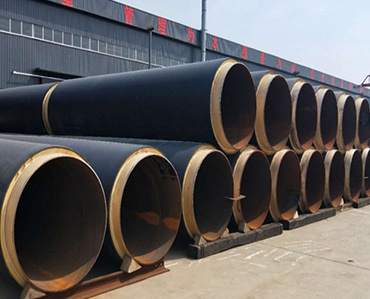

Unlike the traditional laying method that requires compensators and fixed piers, this technology product adopts a unique "internal sliding" insulation structure: the working steel pipe is wrapped in high-performance composite insulation material, and a high-temperature resistant sealed steel outer protective pipe is used on the outer layer, forming a "steel pipe in steel pipe" structure. The core breakthrough lies in the precise mechanical calculation and pipeline pre stretching process, which completely absorbs the huge stress generated by the thermal expansion and contraction of the pipeline network through the strength of the steel pipe itself and soil friction, thereby completely eliminating the compensation wells and fixed piers along the way. This innovation not only shortens the construction period by more than 30%, significantly reduces the cost of civil engineering and the occupation of urban underground space, but also reduces a large number of potential leakage points, resulting in an overall heat loss reduction of more than 15% in the pipeline network. The safety and reliability of the system's long-term operation have been qualitatively improved. The popularization of this technology is providing key equipment support for building an efficient, low-carbon, and intelligent modern urban energy transmission system in China.