The 'steel armor shield' of super hydraulic engineering: TPEP steel pipes ensure the long flow of clean water for thousands of miles

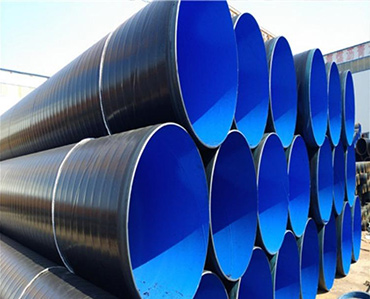

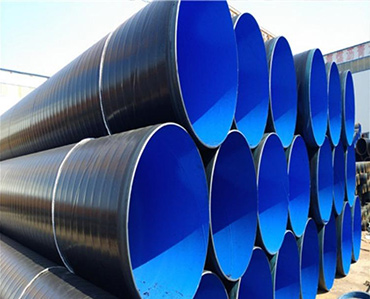

Recently, another major water conservancy project in China's 14th Five Year Plan, the second phase of the "Yangtze River to Huaihe River" water supply mainline, has achieved full pipeline connectivity. In the construction of the hundreds of kilometers long water supply "main artery",TPEP (fusion bonded epoxy powder lining three-layer polyethylene external anti-corrosion) anti-corrosion steel pipe was selected as the core pipe material. Its excellent dual protection performance has laid a solid foundation for the safe operation of this cross century project for a hundred years.

Compared with traditional single-sided anti-corrosion or external PE and internal cement mortar pipelines, TPEP steel pipes adopt top-level protection of "internal and external repair". The inner wall is coated with food grade fusion bonded epoxy powder (FBE), which has a smooth mirror like surface and extremely low friction coefficient. It can effectively improve water delivery efficiency by 5% -8% and completely eliminate the "secondary pollution" and water quality deterioration caused by the growth of aquatic microorganisms and scale, meeting the high standard drinking water hygiene requirements. The outer wall adopts a sturdy three-layer polyethylene (3PE) structure, which perfectly resists corrosion, plant root puncture, and third-party construction damage in the complex soil environment along the line. The successful application of this project marks that TPEP steel pipes have become the preferred pipe material for long-distance, large-diameter, and high standard water transmission projects in China, providing a mature and reliable technical model for the subsequent construction of the national water network backbone.